Overview

This week’s episode comes from Kibera, Kenya’s biggest, and one of Africa’s largest, informal settlements.

Life is tough here, and many talk about the “slum mentality” where a lack of opportunities leads to drug abuse, crime and a general sense of despair.

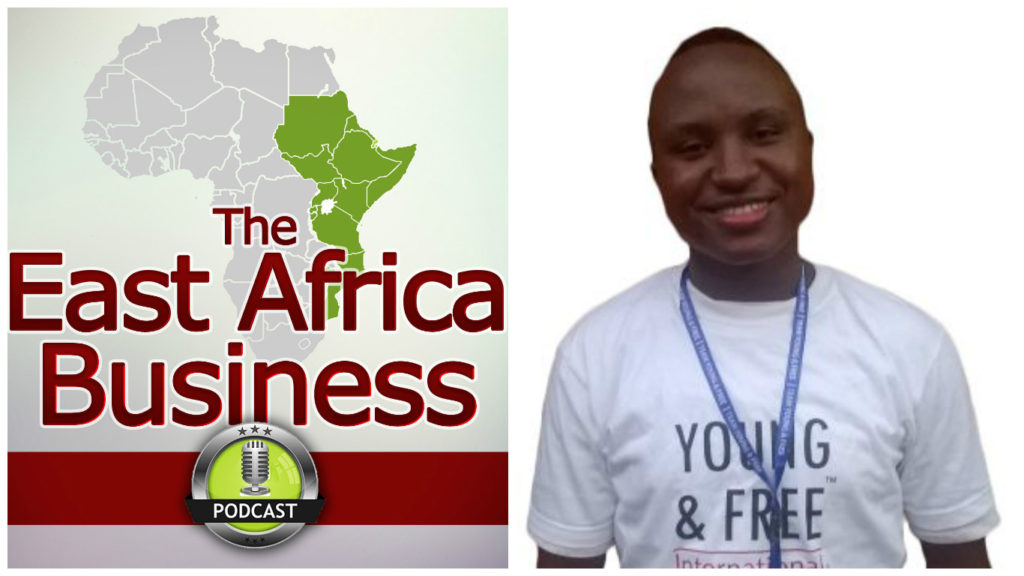

Julius Otieno is an inspiration for those in his neighbourhood.

After dropping out of high school as his family could no longer pay his school fees he combined the talents of his mother (a tailor) and his father (a cobbler) to make colourful, hand-made shoes from discarded pieces of African fabric.

The shoes are a hit, with both Kibera residents and expatriates (such as myself).

Julius and I talk about his story, how the shoes are made, and the impact of the business in reducing environmental waste and providing meaningful employment to the Kibera youth.

We also discuss Julius’ trip to Paris, after he was selected by an ambassador to present at a trade show there.

This involved Julius needing to get funding to get a passport in order to leave the country, let alone have his experience on a plane.

For more information on the business, head to the show notes where you can find the Re-afric website, as well as a blog post I wrote several months ago about meeting Julius for the first time.

You can also head to www.theeastafricabusinesspodcast.com where you can learn about opportunities to help companies like Julius’, whether that be expertise or funding, should you so wish.

Sign up below to hear whenever there are new stories and episodes released on the podcast

Social Media Links

Website: http://www.re-afric.com/

Facebook: https://www.facebook.com/reafric/

Twitter: @reafric

Pictures of me and my shoes

Transcript

Sam: 00:08 Intro.

Sam: 03:11 Cool, so we’re here today with Julius from Reafric, Julius, welcome to the show.

Julius: 03:17 Yeah, thank you so much.

Sam: 03:18 And so to get us started, can you tell us a bit about, a bit about Reafric?

Julius: 03:23 Okay, thank you so much. Once moreI’m Julius Okoth Otieno, I’m a young proactive Kibera resident and the founder of Reafric social enterprise. So Reafric simply means redoing it in Africa, the mission behind the innovation was, I mean, motivated by us being after restoring the original natural state of Africa as a continent and generally, Reafric drives three concepts in our social innovation as a social venture. One is waste management as you know, generally in Kenya both County and national level of our government they are overwhelmed with taking care of waste and this one is very dangerous to environmental pollution majorly in the informal settlements as a pure example kibera slum where I’ve been growing since childhood and the motivating factor was how best can we engage onto activity to clean, bring forth sanitation and reduce the risk of disease outbreak in the slum environment. And in due process of waste, I mean collection with the engagements with the youths and the local County government over here, Reafric thought it wise, part of this waste could be reused to do something tangible. That is what inspired innovation of shoe production whereby we engage into the shoe production of unique, different type of shoe style designs that embrace the nature of Africa and the culture of the population of Africa. And we collect waste like fabric, we call them Kitenge attire, the cut off pieces from the various existing tailors within the slum we also collect like suede, leather, jeans from the carpenters as we know there are a lot of carpenters…

Sam: 05:17 They often use a lot of those things, don’t they?

Julius: 05:21 Yeah, which we collect.

Sam: 05:21 Fantastic. Well, we’ll go through sort of some about how it’s made, but sort of fundamentally you’re making shoes from waste material that otherwise would have been discarded burnt.

Julius: 05:31 Indeed. So we make the shoes out of waste and, apart from waste, we inspire the job creation, to the jobless youths that are, I mean, in the slum. So we mobilize them, those that have expressed their passion through their artwork, we train them and give them work. Whereby now the skilled artisans that are confirmed work and at the end of the day they get paid, and this through sustainable development goal agendas in the whole world, we ensure we improve the livelihood of our employees and 20% of the profit we generate out of the shoe we sell, we plough it back to offer scholarship to the bright needy children. Also, you know, like the informal settlement of Kibera and general slum communities. There are so many existing, bright needy children who cannot afford to pursue their career dreams due to lack of school fee support since even getting three meals a day at the table in their family’s a big deal, which is just but a dream to each and everyone. So we try to mobilize them and after we’ve interviewed them and confirm from their performance and their seriousness with pursuing their career dreams, we offer them scholarship of which the business sponsors their school fee.

Sam: 06:40 Very good.

Julius: 06:41 Yes.

Sam: 06:41 Alright, so there’s a lot, a lot happening in Reafric. So we’ll sort of go through a few different parts. So perhaps just to sort of give, give some context, when did you begin to do this enterprise?

Julius: 06:56 This enterprise, before I officially gave it the full thought and a full attention, so to speak. I began it when I was in form two.

Sam: 07:05 In form two. How old were you then?

Julius: 07:06 I was in form two 2013, 2013 I was 17 years old.

Sam: 07:12 17 years. Okay. So when you were 17. Okay.

Julius: 07:15 Yeah.

Sam: 07:15 And for context you so you grew up in Kibera?

Julius: 07:19 Yeah.

Sam: 07:19 This is the informal settlements, sort of in the center of Nairobi.

Julius: 07:23 Yes.

Sam: 07:24 So you’re in school?

Julius: 07:28 Yeah.

Sam: 07:28 And then form two, age 17, you decided to look at it and do that. Why did, why was it at that time you decided to look at it?

Julius: 07:36 Generally I’m a victim of those that have gone through the struggle of life in the informal settlement of Kibera. So like I didn’t have school fees to support my, my education at high school level. That is from two. And by then my parents quit whatever they were doing in the city and they retired back in the rural at home. So I had to remain alone to ensure I achieve my career dreams. And, to them, they didn’t have anything to support my, my school fees. Like I thought of how best can I look on to something that can sustain me. And I began like hawking the shoes as a hawker.

Sam: 08:16 Hawker. What does hawking mean?

Julius: 08:18 A hawker is like these people that are walking in the street selling stuff.

Sam: 08:22 So you’re sort of standing, you don’t have a shop, but you’re just going selling things?

Julius: 08:27 I convinced the various existing people that are making shoes. Then I go and hawk. So from there I realized like the products were not working for me because it was like a holiday of (3 months a year), like April, August and December and I have to gather or collect what can pay for my school fees for the next term. And this one was not working.

Sam: 08:49 Okay. So why was it not working?

Julius: 08:53 A lot of these common products all over, of which there are so many hawkers, so many shops, so like I could not get my market well.

Sam: 09:03 You couldn’t differentiate because you were just selling the same things as the others.

Julius: 09:06 Yeah, the same things that I was not even getting the flow of cash.

Sam: 09:09 Yeah.

Julius: 09:10 I mean, in terms of revenue and profit to sustain me. So like the idea was how best can I venture onto something outstanding that can beat the market, not more competitive and it will sell with ease and get enough cash to take me to school when the school opens. And that is what drove my, inspiration to innovate this unique shoe products that are being made out of different materials, extracted from waste.

Sam: 09:37 So why did you choose shoes? Like why did you not choose to sell food or to do anything else?

Julius: 09:44 Generally my mother is a tailor.

Sam: 09:46 Okay.

Julius: 09:47 And my dad was a Shoemaker.

Sam: 09:48 Oh really? Your father was a Shoemaker?

Julius: 09:50 Yeah.

Sam: 09:50 So I see, so did you, did you know how to make shoes?

Julius: 09:54 Yeah. I know how to make shoes. We grew up, we grew up making shoes, even repairing shoes like yeah, my mum is doing tailoring and she is contributing to the waste emission and my dad is making shoes but does not know and I have not come to realize that this waste that is being emitted by my mother can be reused as raw materials for the shoes.

Sam: 10:14 So their whole life they’ve been doing their current businesses and you’ve come along and said actually… We can combine them and bring forth mutual partnership among the various existing businesses.

Sam: 10:26 Where did you get, because the shoes there are quite cool. Like where did you sort of get the inspiration?

Julius: 10:33 Actually? I didn’t see anything to inspire me but I thought giving it, I had a new unique idea that why don’t we make shoes out of different material that have never been seen. Yeah. And I say no, let me make the shoes out of fabric because most of the Africans are after the fabric attires.

Sam: 10:57 Yeah.

Julius: 10:57 Why don’t I also serve their feet with a similar attire they put on.

Sam: 11:01 Yeah.

Julius: 11:02 And that is how like the fabric kind of shoe products came about..

Sam: 11:07 And I should also note for listeners at the moment, there might be some motorbikes going on in the background, so if there’s a bit of extra sound in the background, that’s just what it is. Actually perhaps let’s talk about it. So we’re, we’re here in actually we’ll get to that in a bit. So you’re age 17, you have the idea, you think actually I can, you know, start to use these tailored product, you know, the off cuts of fabric for making shoes and you already have experience on how to make shoes. What happens then?

Julius: 11:37 I didn’t have the full concept on how best I this bring this dream or innovation into reality. So what I had, it is like and moved from various existing skill artisans that are working on general shoe industry and I went to pick the professionals or the owners of those small shops and I brought them on board. And I told them I have this new unique product that can supplement onto whatever existing shoe product you have, can you try it out. And we test it if it can sell in the market. And I confronted like 10 and only 6 responded, 4 didn’t respond immediately. So when they responded, six because I didn’t have the capital or whatever it takes. So like I could like say, can you use whatever you have to do for me, this number of pairs of shoes. Then I try to Hawk I’ll pay back and through that concept, the first week I did the hawking, I made like four times revenue of the normal ones, I used this normal, I mean shoes that are common in the market, are you getting it. So I told them this things can sell and that one was within just Kibera.

Sam: 12:51 And you were, you were hawking still?

Julius: 12:53 Indeed.

Sam: 12:53 So you went. So this is quite smart. So, rather than trying to get your own, make the shoes yourself, you just went to somebody else who could make them.

Julius: 13:04 Yeah.

Sam: 13:04 And you basically said, here are the materials. If it sells, I’ll give you some money.

Julius: 13:08 I’ll give you some money, if it doesn’t sell. And it is my time to go back to school, I’ll return to you the shoe.

Sam: 13:13 Yeah.

Julius: 13:14 Because you’re the one who incurred the cost of bringing it here. So, and they agreed of which in due seasons during holidays, I come back in the slum and I go to them, they do the production, I hawk and I began to save after clearing my school fees, saved. And I think after form four, that is 2014, 2015, I mean, I went to Tunapanda Institute.

Sam: 13:39 So by this time you’re how old?

Julius: 13:41 I was 20 years. That is like 2015. So like I gained the passion and interest to learn whatever, what business means or what the business world fully entails. So from there I went to Tunapanda, I did basic ICT.

Sam: 13:57 What is Tunapanda?

Julius: 14:00 One of the various existing vocational institutions within the slum of Kibera that offers free basic ICT training in combination with entrepreneurship.

Sam: 14:14 Okay. Who runs Tunapanda?

Julius: 14:16 Tunapanda is owned by Meek and Jay, these are two brothers from the US, yes. It is just just near by within the Olympic estate.

Sam: 14:25 Okay. What were some of the key lessons that you learnt in that program?

Julius: 14:31 Tunapanda? Basic ICT skills generally in programming both website and graphic design and what I enjoyed the most was entrepreneurship, that is business, whatever it entails and basic accountings.

Sam: 14:48 Very good. Okay. And how long did this program last?

Julius: 14:52 The program is only three months. Very intensive so to speak because you’re committed full time.

Sam: 14:57 Yeah. Okay and what did you do afterwards?

Julius: 15:01 What I did is I didn’t even give the business a thought still because I was fearful it would be a struggle since there was no capital or whatever it takes to implement the venture fully. So I, from Tunapanda, I went to work in a company called Samasauce.

Sam: 15:20 Samasauce?

Julius: 15:21 Limited company.

Sam: 15:22 Okay. What do they do?

Julius: 15:23 So Samasauce is a technology company based in Kenya that is building on software developments in partnership with the various existing big companies like Google, LinkedIn, Facebook.

Sam: 15:37 So it’s kind of like outsource, outsourcing?

Julius: 15:43 Yeah.

Sam: 15:44 Cool. So there’s this, so Samasource is the company and then you joined them. So because you have some ICT skills.

Julius: 15:51 Yeah.

Sam: 15:52 You could then go and join them and that’s a way for you to earn.

Julius: 15:55 That is how I begun sustaining myself after that. And they were paying only $200 in a month and then…

Sam: 16:05 You had ambitions for more?

Julius: 16:07 Yeah, I had ambitions for more so like, I worked there for two years. Then after working there for two years, I also used to give a change kind of lecture or speech to motivate the youths because over 80% of employees in Samasource were youths and their lifestyle sometimes is wanting, in our society so like, I used to volunteer and like mentor or nurture the colleague employees, youths that are existing there. And I think from there is where I began realizing my potential and what life means for me because most of them were saying, no, you should not be here. You should be somewhere doing something to our society. Most of them, all my friends, even the managers, my bosses, so to speak. And from there, like one day I thought of making the shoes and display to them.

Sam: 16:57 To the managers?

Julius: 16:58 To the managers. And they bought the shoes and they presented the shoes to the executive team and they showed the shoes to the CEO of Samasource. She’s called Layla Jana. And when she got the shoe, they told me, she told me because she’s running a social venture, with a social impact with it. So when I described for my mission, she like said no, quit this job, go and do whatever.

Sam: 17:26 So the CEO told you to quit your job.

Julius: 17:28 She told me, make sure you are supposed to be employing more people, nurturing more people in this society and impacting lives. So the best thing don’t fix your mind here. Please quit the job. I didn’t even like hesitate, I give it three days, then I quit that job within three days, they allowed me and I came and launched this social venture fully 2017 September. Yes.

Sam: 17:56 Okay.

Julius: 17:57 Yeah.

Sam: 17:57 So what did the what did it, what was your life like at the beginning, was is just you do, did you have other people who could help out with the venture?

Julius: 18:08 It has been full of struggle so to speak because I’ve not yet gotten the hands, both locally, internationally, so to speak enough hands that can help it. And from the beginning I can say like it was a very big struggle because making a team from the informal settlement to build a company with them is the most hectic thing to do. So we began three of us, Peter over there and Selly, the one making beads here. We began three of us. So…

Sam: 18:43 Back in 2017?

Julius: 18:45 2017 September.

Sam: 18:46 Are they your friends? Did you know them before?

Julius: 18:48 I just knew Peter as a shoe maker who could make the, part of the team would make the shoe when I was hawking then I go and sell, but later I came and said can we now form a mutual partnership together and form a team as a company, or a social venture. And he agreed, but Selly was a friend, even though he’s more into sandals, bead work and he also joined the team. Yeah. So because there were only two and the business was growing and there was lots of demand, and I began like dominating the market by testing the product and confirming the interest of the clients in the market. So like we begun now what can we do to ensure we have enough capacity? Are you getting it to deliver the demand?

Sam: 19:36 Who were the first people who were buying these shoes?

Julius: 19:40 The first people were the local Kibera residents.

Sam: 19:44 So other people who are living in Kibera, I’m trying to picture it. So you’d have a bag of shoes and you’d go around to different shops and say would you like to buy these shoes?

Julius: 19:58 Yes, that is how we began. And I used to do sales by myself so like I could do, go and talk to various people and showcase the product. Go to various functions when I’m dressed like a “crazy” African, plus my feet, when you question about i, I direct you to the shop. Then you place an order, we produce and deliver to you. So people around are very well conversant and aware of the products because they were there fast.

Sam: 20:27 And what were you calling them?

Julius: 20:31 I used to call them sick shoes.

Sam: 20:33 As in like I’m sick?

Julius: 20:38 To attract the attention of a client or customer, who might, I mean diminish you or like deny you a chance to communicate or sell your idea or product to him/her. I say no. Have you ever heard about sick shoes? Sick? You want my feet to be sick? No, they’re made out of waste. So like, you know, we extract that which can negatively affect the society, we use it as a raw material, and now we do what, we make the shoe out of it. And that is how people began to entertain and enjoy.

Sam: 21:12 Oh, very good. Okay. So that was those are the first few months. What was the next big break for the company?

Julius: 21:20 The big break was now end of 2017, 2018 February, I joined the Somo project. Somo gave me the full knowledge of whatever entrepreneurship fully entails, in line with the concept of social innovation. And after joining somo, they gave me funding. That is after three months or so. Intensive kind of training.

Sam: 21:50 So I’m trying to explain, the Somo project is an organization in Kibera.

Julius: 21:50 Yeah.

Sam: 21:52 Where people come, people like yourself come with ideas.

Julius: 21:54 Yes.

Sam: 21:55 It sounds a bit like this Tunapanda program,

Julius: 21:58 Indeed, yes.

Sam: 22:02 They kind of take you through how to have an eye to progress.

Julius: 22:07 So with Somo, if I can differentiate it from Tunapanda, Tunapanda just gives you the skills and then they can either help you look for a job. Yeah. But Somo ensure that whatever they nurture you in, is a venture they believe in and at the end 80% of people that are going through their program are invested in.

Sam: 22:29 I see.

Julius: 22:30 Yeah.

Sam: 22:30 So it’s much more about almost an incubator. It’s like that sort of thing. I should note that we’re actually doing this interview in the Somo projects container.

Julius: 22:42 Yeah. This a Somo project container.

Sam: 22:45 The office is like a shipping container. So we just said hello to Amelia and the people who run it. And they’ve kind of let us use their.

Julius: 22:54 Indeed.

Sam: 22:54 Shipping container a bit.

Julius: 22:57 They even offer you the working space, to offer meetings, generally even to do your stuff. Yeah. This is why this container spaces are existing here.

Sam: 23:10 Fantastic. Okay. So you’ve got onto the Somo project program. At the end of it you get investments?

Julius: 23:19 I got a small grant.

Sam: 23:19 Small grant, so that sort of allows you to start.

Julius: 23:23 Yeah. Like the, it was Ksh 185,000.

Sam: 23:33 That’s $2000?

Julius: 23:34 Yeah, two thousand dollars. So like that is what I used to buy the two machinery, you see there and the small grinding machine and there are so many various existing tools, equipment and even a few shoe molds, I used the very grant to purchase them. Yeah.

Sam: 23:50 So after Somo project has been completed, at this stage, who is buying your shoes? Like who else was buying the shoes?

Julius: 24:01 Generally, in partnership with the Somo project, I have been in a good position to have an exposure to not only in Kibera, not only in Nairobi city, not only in Kenya, not only in Africa, but globally. That simply means like we managed to make our website, create our social media pages and Twitter handles, so to speak, whereby we can now speak about our brand products to the world and those that have interest or are after to get the shoes they communicate farther and then we negotiate on how we can build the production, deliver all over the world whereby we segment or market to be both local and foreign and we target our main target are the youths age 15 to 40, who are passionate and much more interested in the shoe products more so in the current trending fashion design crazy world. Yeah. So like we go to university students to, to market the products and even in the various occasions that we apply to either pitch, we have also various existing exhibitions in Kenya which we attend and the showcase our products. And there are clients who walk in, there are tourists who come to Kenya and sometimes find their way to Kibera slum and they can pass by the shop, familiarize themselves on the product and pop in to inquire more and even buy I can say even the Somo staff the Somo board members and generally their network, the mentors Somo organization has, even Tunapanda and that is how we get to access our market.

Sam: 26:00 Very good. Okay. And so now, now you have these various different channels by which people can come in and purchase your shoes. So if we look at the, you know, when you first started it was all quite informal and it was, you had Peter who was making the shoes your other friend as well and you are out Hawking. What does the operation look like now in terms of the production of shoes? How, how is that, how would you explain that?

Julius: 26:30 I can start by saying, I mean like when we were three, now we’ve grown to be 15, 15 pro full time producers and we have another 12 brand ambassadors across the world. And Sam you are part and parcel of our brand ambassadors, as I saw you telling a nice story of our brand products in your website,you are part and parcel. So like there are volunteers who are like can tell a story or can share their experience with our product to their network, which as Reafric, we are not accessible or not aware. Yeah. So that one like and also we have like,I can say a small people, a few people who do like hawking and those that we are in partnership directly to, I mean accept our shoe products in their shops as a supplement product to their I mean, shoe products. Yeah. So these are part and parcel of the team which make it to be 42 in number.

Julius: 27:36 Very good. Okay.

Julius: 27:37 The active shoe producers are 15.

Sam: 27:39 People working, so 15 people every day and, and what, what are those 15 people doing, are the majority of them making the shoes?

Julius: 27:46 Yeah, all of them are making shoes, shoemaking is in different stages.

Sam: 27:50 Okay. So I’m really interested. All of the shoes you make are from hand, so from scratch like…

Julius: 27:56 Yeah.

Sam: 27:57 So what are, how many different types of shoe do you make?

Julius: 28:02 We have like I mean kind of five different types of shoes. Okay. You have the official leather for the official attire in the official nature, we have the Maasai sandals and we have the toughees back to school leather and now we have like the fabricated ones, type and now we have a mixture design. A mixture design can be either leather and fabric combined or suede and jeans combined or like jeans on its own. So these are different designs from the normal four we began with. Yeah. So they are like five different types.

Sam: 28:43 Okay, and then within, for example the fabric, there are different styles. There’s, you have men’s shoes, lady shoes, some with heels, some are boots, et cetera okay. And then I’m interested, the actual fabric that you get on it, see within that, there are lots and lots of different options for what the fabric can be on the shoe. All right. These are bits of fabric that would otherwise be thrown away.

Julius: 29:13 Yes.

Sam: 29:14 So from tailors. How does that work? Do you sort of send people out to go to different tailor shops and see what artwork is available?

Julius: 29:25 We give it different approaches. We have like cleanup programs that are currently organized by the inspiration being driven by Reafric in partnership with the various existing organizations. And the local County government as at now I can say have a hand in it and I see the Nairobi governor Sonko is even currently organizing they clean up, I mean kind of forums. Saturdays, once in a month. So in due process, Reafric now has a team of 356 youths who do like daily, I mean cleanups in different parts of the slum because the slumis segmented into different villages, there are around 13 villages. So you’ll find a team today in Olympic Fort Jesus, 42, Jamhuri Woodley, I mean Katwekera, various existing small villages. They’re like estates, but we refer to them as villages, because it is an informal settlement, where like, they do clean up. So we have a team 356. So out of this 356, each and every team we have, we’ve segmented them to be like in a team of 50 and they have team leaders, so 50 50, that is like I mean 350 and then 6 of them leading these seven. I have on my team, I lead a team, one of the 50 which make it to be 357. So like as leaders we ensure like this 50 are doing cleanups in the various parts, but with us we try to talk to the waste emitters, people who throw waste like these small existing industries. We have a so many tailors, almost 1000 tailors in the slum and there are lots of carpenters. You know why? Majorly, these are the cheap means through which they can generate an income or this like, the easiest kind of job they can learn and adapt to. And they do it from their small production site and they emit a lot of this waste, carpenters also emit waste. And now as leaders who lead these teams, we go to them. So don’t tell me to waste, package them somewhere, then you’ll come and pick them as waste.

Sam: 31:54 Okay. Do you pay them for waste?

Julius: 31:58 We don’t pay, we pay for some of the waste.

Sam: 32:02 Really?

Julius: 32:02 Yeah, when you do sorting and they realize this portion of our waste is going to be used as a raw material, and generate money with it, you have to pay.

Sam: 32:10 Yeah.

Julius: 32:10 Yeah.

Sam: 32:11 Okay. So, so people, I imagine that would make people more thoughtful about, before throwing away something. If any of that…

Julius: 32:17 Initially, when we began, we were not paying.

Sam: 32:19 Okay.

Julius: 32:20 But when we go to sell for them shoes, that shoe is out of this waste you used to emit carelessly, we didn’t realize that they’ll now demand to sell to us the waste.

Sam: 32:30 Yeah, they’re smart.

Julius: 32:32 So we pay for some of them. Majorly, those that they consider we use as a raw material, they know how to sort them themselves, put them different from the waste that will automatically go to the dumping site.

Sam: 32:44 Got i.

Julius: 32:45 Yes.

Sam: 32:45 Okay. So you then go and you collect these things and then do what? You take them back to the shop?

Julius: 32:51 To the shop.

Sam: 32:51 To the workshop. Do you have one workshop?

Julius: 32:55 I don’t have one workshop as at now, I have three. Yes, that space is too small and sometimes you may wonder why is it people a few. That space can only accommodate 9 in maximum. So like I have three more people like Peter, whom I’m in partnership with and like I own that one shop, workshop, but the rest of the two remaining workshops, I partner. I partner in terms of referring the trained, already confirmed skilled artisan youths to be part of that team and then I give them a job.

Sam: 33:33 Why don’t you own the other two? Why don’t you, why do you use two other people that you don’t? Why you partner? Why don’t you just do it all yourself?

Julius: 33:41 The thing is we are limited in capital. Just to set up a fully fledged production capacity or production space to accommodate the entire team.

Sam: 33:50 Okay. So you have to, at the moment, you partner with other people. How does it work? Do you say I’m gonna pay you this amount to produce the shoe?

Julius: 34:01 Yeah, so like when I have orders, I give them or when, because there are a lot of demand of these rendered jobless youths who have passion in artworks. So like after confirming them, because my space currently is very squeezed, I take them to the team, the rest of the two, I mean workshops I’m in partnership with and I say no, take these three skilled artisans, put them under you. Even though they are subjected under them, Reafric is the one who would cater for their cost, payments, salaries and all that. I’ll be giving you order. You watch over them. It doesn’t mean I don’t like, like I own 30% or 40% of the other workshops, yeah because I have to take few tools, equipment, to make these specialized, fabric shoes, which they didn’t have initially before I met them. Yes.

Sam: 35:02 Okay, cool. Are those also near your main workshop, these two places, they are close by. Yeah. Okay. Do you have the fabric? How long does it take to train somebody to be able to make a shoe?

Julius: 35:20 It depends. It is a duration of two to four months. When somebody, yeah two to four months and also like depending like we’re training how many.

Sam: 35:31 So let’s say you’ve got four new people.

Julius: 35:34 Four new people will take me four months, two people will take me two months. Okay. You know why Sam? I have two sewing machines. So space will be shared, which is really limiting.

Sam: 35:46 I see. So in what, is there a part of making the shoes? Is it they have to be able to use a sewing machine?

Julius: 35:53 Yeah. They have to learn it. The theoretical and practical part of it.

Sam: 35:57 What’s the theoretical parts?

Julius: 35:59 When we explain to you how the shoe is being made the way I was like explaining to you. You know practically now you will be subjected and be given somebody who is more professional to, to handle you by you seeing now what he it doing? And he’s like telling you do like this until you become perfect. Yes.

Sam: 36:19 And when people have learned how to do it, do you have like you give them a test and you say here’s an order, you’re going to do this completely on your own. Is that how you know that somebody has the skills to do this.

Julius: 36:36 But it takes a while to confirm somebody to be a full professional, perfect skill artisan that won’t be disapointed with a client or the product and this one relies on the more professional people that I entrust this onto their hands. So like we first give, I mean tests, I say make for me, two pairs of shoes, I’ll put them on for the next two months and be running errands with them. And I’d be, I mean viewing them and the verifying the quality, durability, the mistakes that might cost the defect thereafter. Then with time, as you are being tested on that concept. You improve on your perfection and you will be in a position to be even more professional than even your trainer. Yes.

Sam: 37:26 Okay. Nice did you find that there are many issues with the production cause there, I’m trying to think, it might be quite to me it seems that there’s quite a number of steps along the way. Is it something where there that there is things can go wrong or like how, how do, how would you sort of think about the production side.

Julius: 37:47 Issues might be there in terms of poor coordination, poor communication and sometimes misunderstanding in the team, which some you might give an order, they fail to deliver. And that is what made me to hire the management team. So that before a final product comes to us for verification, the executive team, director, the management team has confirmed, qualified, verified and gotten the product satisfying to be delivered to a client without any defect.

Sam: 38:27 So you kind of at like quite a good stage, you know, like roughly how many, if we were to look at like actual numbers of shoes that you’re making now, what would you say is like in a typical month, what’s like a normal amount of shoes that you’re actually making?

Julius: 38:42 Around 150.

Sam: 38:43 Do you think there is demand for more than 150 shoes?

Julius: 38:47 Yeah, I ignore a lot of orders.

Sam: 38:49 You ignore them?

Julius: 38:49 A lot of orders.

Sam: 38:50 Why do you ignore them?

Julius: 38:52 Sam, tomorrow you can come from UK and tell me I have a thousand clients who have paid for it, but I don’t have the capacity to deliver that in terms of the limited machinery tools and equipment and I’ll ignore that. Also, in accordance to the urgency of the order, which will not be in a position to deliver.

Sam: 39:12 Just talk me through the working capital side of the shoe. So like roughly how much do raw materials cost, where do you buy them from? Do you have to keep inventory?

Julius: 39:22 We have various existing raw materials from different industries or suppliers like the shoe sole itself is from a different, a totally different, I mean supplier because it is a recycled cutter, which is a final product, which in the real term, we use a raw material, we buy it, the only thing like through buying it or using it, we contribute to environmental conservation and preservation.

Sam: 39:53 Where do you buy it from?

Julius: 39:55 We are like Makina, but they are being recycled in the, I call it industrial area, nearby the city.

Sam: 40:03 Got it. So in within Kenya there is a company that takes old tires, recycles them, turns them into soles and so these would need to be, so you have various different sizes. So when you go…

Julius: 40:20 It is a sheet like this.

Sam: 40:20 Okay, this is a big long sheet. I see.

Julius: 40:25 Did you see how we smoothed than the grinding. So let you know when you cut it, sometimes you cut it big or it was not straight or uniform, you have to correct. So that is the purpose of the grinder.

Sam: 40:40 What, and so you obviously you need, do you need to pay cash for that? Can you, can you buy that on credit?

Julius: 40:46 On debt it?

Sam: 40:47 Yeah. Can you get it on that?

Julius: 40:49 You cannot get it on debt because we’ve not signed up an agreement on how to lay a permanent partnership with our suppliers. When does the customer pay you? Do they pay you on delivery? Do they have to put down a deposit?

Julius: 41:04 Clients, we have the percentage deposit will cover the working capital which some hesitate to commit to, they want a final product, just cash on delivery but the clients with whom we are currently serving, that’s why we have limited orders to 150, we get a lot of orders.

Sam: 41:28 Okay.

Julius: 41:28 There are people would say yes I mean the upfront fee to cover the working capital is 75%. Let me commit this and the rest of the remaining percentage of the shoe price, we’ll commit it on delivery.

Sam: 41:44 And then talk to me about the machinery. So what are some of the fixed costs that are necessary in your shoe operation? So you spoke about this grinding machine or, what are some of the other things which are important?

Julius: 41:57 We have the sewing machine.

Sam: 41:58 You’ve currently got two?

Julius: 42:02 Currently I have two, but I have like 10 people, 10 employees, sharing the two.

Sam: 42:11 Sharing it. Okay.

Julius: 42:13 Yeah. So we are really limited with this as a fixed, I mean capital cost. We have the grinding machine which I showed you. We need at least five. We have one. That one is the Old version manual. We’ve just modified it to be electric. So we need like a minimum of five.

Sam: 42:32 Okay.

Julius: 42:33 And also we have the shoe molds, which is a big kind of threat to us as we are growing in terms of delivering the demand. So they shoe molds like we need currently 300 to 500.

Sam: 42:46 Okay. So with the sewing machines. So with all of the shoes, you need to do some sewing.

Julius: 42:57 Yes.

Sam: 42:59 And so every single shoe that you have needs to go needs to have some sewing.

Julius: 43:05 Yeah.

Sam: 43:06 But the fact that you’ve only got two sewing machines makes it so it means that you’re limited by the number that you can make.

Julius: 43:13 Production, yeah.

Sam: 43:14 So does that, so that means that every day, every hour, there’s somebody sat of that sewing machine.

Julius: 43:21 Indeed.

Sam: 43:22 If you were to, is it, so you currently got two, if you were to get eight more sewing machines, does that mean that your production would increase by four times or are there other factors? Which means that that’s not the case?

Julius: 43:37 That is the case because as I know I have, like Sam I have 50 pending, youths who have expressed their interest to be skilled artisans into our footwear industry, but we can not absorb them because the space is small, the machinery feel. So like in regard to your concern or question is like, we need more machinery to ensure people don’t share machinery and somebody at the end of the day, an employee delivers the job, in accordance to the demand in the market. But when they’re sharing, somebody is maybe limited, and all of them are ever limited.

Sam: 44:26 There’s always, always stuff that can be done.

Julius: 44:28 That it’s like a limitation to deliver the demand, are you getting it? And that is what make us to ignore more of the orders. Yeah. So we need like the machinery whereby the number of employees which, whom we’ve already confirmed and are permanently working with us, at least each and everyone has his machine. Yeah.

Sam: 44:55 Okay.

Julius: 44:55 Tool and equipment tool to help them in operating in a harmonious way.

Sam: 45:01 And how much does a sewing machine costs?

Julius: 45:04 So the sewing machines vary. The normal old ersion, which we have cost $750 but, and the best sewing machine that can deliver the work and do a quality, I mean work cost $2,500. Yeah. So that is the cost of the kindly needed sewing machine, with our sensitive, unique kind of shoe product we are making, which we are straining to perfect the quality and keep on our standard. In as far as the competition in the, in the market is also concerned I will prefer that latest version of the sewing machine to be put into consideration.

Sam: 45:55 Yes. How much do these plastic molds cost?

Julius: 45:58 A pair of shoe molds in Kenya cost $40.

Sam: 46:03 $40. Really?

Julius: 46:04 $40.

Sam: 46:04 For just a bit of plastic. Sorry, it’s obviously more than a bit of plastic.

Julius: 46:09 That is 4,000 Kenya shillings. And that one, when I go to buy in bulk, like 10 pairs, that is my recent purchase.

Sam: 46:18 That’s so insensitive. Okay. So that’s, so if you’re looking at the things which are limiting the growth of the company.

Julius: 46:27 Yes.

Sam: 46:27 So machines, these molds and the growing emissions.

Julius: 46:32 We also have the small things as tools and equipment.

Sam: 46:39 Okay.

Julius: 46:40 They are invisible, but without them you can do nothing.

Sam: 46:43 Roughly, what margin do you make on your shoes? So roughly how much they sell for?

Julius: 46:50 For apair of shoe to be completed is $20.

Sam: 46:53 Okay. So $20 and that includes, inclusive of labor?

Julius: 46:56 Yeah. Labor fee.

Sam: 46:58 Includes labour fee.

Julius: 46:58 Yeah. And I sell it at $40.

Sam: 47:02 Okay, so you making roughly $20 per shoe?

Julius: 47:05 Per shoe. So like that is 100% profit. Yeah.

Sam: 47:09 Yeah. Okay. So it’s roughly $20 to get them made, $40 to sell them. But of course if you’re sending internationally, you’ve then got the delivery cost as well.

Julius: 47:18 Yeah, we put the delivery, which goes up to $80, $90.

Sam: 47:23 Okay.

Julius: 47:24 Yes.

Sam: 47:24 Cool. Okay. And so what do you, what do you see next for the business? What, what’s your sort of ambition for where the business can go?

Julius: 47:34 I can say I’m very much hopeful with this social venture because you know, if I could think of even selling the shoe, meeting the world and just getting the profit or investment to expand it and let it grow my passion is what is, what does it do or what is the impact it brings to their society? Because I see so many youths languishing in these streets, the slum, engaging into crime activities like robbery, thuggery. Destroying people’s properties, engaging into riots, being spoiled by politicians. And this one is being driven by the fact that they are unemployed and they have nothing tangible to keep them busy. At the end of the day, they don’t have something to sustain them and they’re just hopeless, and you know a hopeless society is a society that is ready for blood, ready to do something like in the name of crime as their means of survival. Are you getting it? What if not only Reafric, but even the various existing social innovations or institutions. What if we bring these people on board? We tell them life is possible. I realize your passion, let’s help you build on it and then we acquire you fully in our team. And at the end of the day, this one becomes an income generating activity that is sustaining your livelihood. What if we are in a good position to give back by, for example Reafric offering scholarship to these bright, needy children who have very bright future, very sharp and can at one point be great people in their society. Not only in this slum, not only in our nation, not only in Africa, but at one point the entire globe. What if we give them the chance by like supporting their career dreams? Yeah, because most of them are school dropouts and that is what contributes to the high rate of unemployment crisis. These people cannot even, they’re not graduates, they don’t have any skill that can expose them in the job market or can inspire them to initiate something tangible, are you getting it? What if we get hold of their hands and build, help them build on their careers and give them only like, I mean, 10 years maximum, they will be people who are great in the society. Somebody can now go on and further his/her studies abroad or pursue a career of his/her dream with ease, are you getting it? Once their foundations are well laid. Okay. What if you’re in a good position to expose this unique fancy product to the globe? To the global market? I mean, are you getting it? I went to France and Sam, over 80% of the population that I engaged with were interested to buy the shoes. I didn’t have any pair of shoes.

Sam: 50:40 Let’s perhaps talk of this. Do you, were, you recently went on a plane to Paris?

Julius: 50:45 Yes.

Sam: 50:46 And spoke at a conference. How did that come about?

Julius: 50:51 Through the various partnerships which I have in Kenya.

Sam: 50:57 Within Kenya you’ve got, there’s a parnert, you partner with the French embassy or something?

Julius: 51:03 No, I don’t partner with the French embassy as such. I am one of the youth leaders in one of the biggest organization. We call it an umbrella body, umbrella body of the social enterprises in Kenya, this called social enterprise society of Kenya. SESOC. S I’m one of the founders or co-founders of SESOC because when it was starting with that people who get in. So it does over a hundred different entrepreneurs. So the CEO of SESOC always speaks about our social ventures in general and those that are interested either in buying our product, engaging in partnership or networking on either a different way. They just call you. So when SESOC went to speak about our social venture in the French embassy the french commissioner was there and he was the organizer of this summit in France. It is called packed for impact.

Sam: 52:02 Packed for impact, okay.

Julius: 52:03 So when it came to Kenya, he was looking for two Africans, who can accompany him there.

Sam: 52:09 Yea.

Julius: 52:09 Yeah, because it was a global thing. And when this it talked about all the hundred and 50 ventures, he found an interest to come and see my venture. So when he paid a visit in the, in our shop and verified everything, he found an interest that I may go and give a speech of this to the world, yeah.

Sam: 52:31 So you, was this your first time on a plane?

Julius: 52:34 Yeah.

Sam: 52:35 How was it?

Julius: 52:35 Yeah. It was great but I feared the plane, it goes so far.

Sam: 52:41 Yeah.

Julius: 52:42 Yeah, I feared but I enjoyed it. At the end of the day we are over 300 people on the plane. So there’s is nothing to fear. People are just walking here and there.

Sam: 52:56 Did you watch a film?

Julius: 52:58 Yeah, a lot of films. Yeah. I watched films. Yes, indeed. It was a very great, and to me it was an inspiring experience, so to speak. Yeah.

Sam: 53:08 Nice. What did you think of Paris?

Julius: 53:13 I’m sorry, you know, like it was very funny being out of Kenya, my first time and my dream had been to be in London, New York and Dubai, Paris was very cool.

Sam: 53:27 And you, you might be going back again soon.

Julius: 53:29 Yeah. I’m looking forward to go back. I’ve been given an official invitation letter to go back September. Yeah. Because the team which I met had seen the potential behind the innovation and are considering it to be well spoken or communicated to the world. And the summit, which I went in the past was only having a thousand people and this one has 10,000 people. So with my passion or I mean not even passion, with my vision of dominating the global foreign market, I thought it wise that the, so many different people from different ethnic backgrounds in terms of profession, business wise, government officials, investors, donors and I’m just aiming on how best I can get people who will come one-on-one. They position the table to help me set up the shoe shop across the European, I mean markets in the major cities. And I think that is what is driving me to look on how I can go back.

Sam: 54:36 Yeah.

Julius: 54:36 Even though we are still in negotiations as I told you.

Sam: 54:39 Well, that might be quite good placed to, to finish it, Julius. I mean, thanks. Yeah, really, really interesting chat. The whole story from the beginning, you know, you starting out, you seeing the idea, all the influences you’ve had along the way the place you’re at right now where there’s great demand for a product but you’re kind of limited, limited by the capital that you got in the business. If anyone’s listening and they’d like to learn more about the company, they’d like to perhaps buy some shoes or even look at you know, if they can think of any grants that you might be applicable to or perhaps come on as an investor, what is the best way for people to learn more about what you do.

Julius: 55:24 We have our website where we have the full information on the product varieties and how best you can either engage, by either buying or contacting us directly. We also have our Facebook, Instagram.

Sam: 55:40 The website is R E dash A, F, R, I. C?

Julius: 55:45 Yeah, that is R E dash, A, F., R, I, C. Reafric.

Sam: 55:51 Reafric.Com.

Julius: 55:53 Afric of Africa. So yes .com. So that is the website through which once you Google, you’ll find us and see whatever we are doing and the product we are making. Yes.

Sam: 56:04 And you’ve got Facebook?

Julius: 56:05 Yeah, Facebook page, it is just Reafric without the space or hi fen, Reafric page then Instagram too, Reafric, Twitter handle is Reafric.

Sam: 56:17 Got it.

Julius: 56:17 Yes.

Sam: 56:17 And we’ll link to all of those in the show notes as well, so people can head to The East business podcast.com

Julius: 56:24 Okay.

Sam: 56:24 And they can find the show notes for this interview and we’ll link to all those, as well as some pictures that we’ve taken today. Wow, very cool. Well Julius, thank you so much?

Julius: 56:34 Thank you so much to Sam for the time and having the passion with whatever we are building.